AMERICAN SOCIETY OF CIVIL ENGINEERS

INSTITUTED 1852

TRANSACTIONS

Paper No. 1191

WATER PURIFICATION PLANT, WASHINGTON, D. C.

RESULTS OF OPERATION.1

By E. D. Hardy, M. Am. Soc. C. E.

With Discussion by Messrs. Allen Hazen, George A. Johnson,

MorrisKnowles, George C. Whipple, F. F. Longley, and E. D. Hardy.

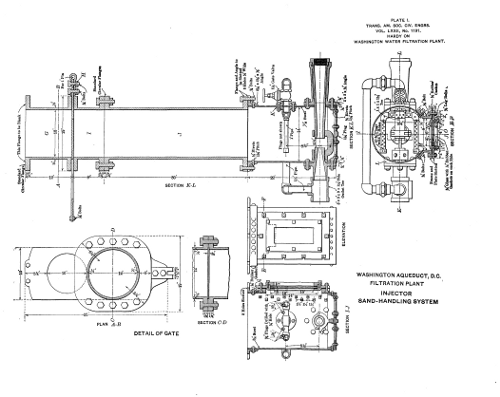

The Washington filtration plant has already been fully described.2 Atthe time that paper was written (November, 1906), the filtration planthad been in operation for only about 1 year. It has now been incontinuous operation for 5 years, and many data on the cost, efficiency,and methods of operation, have accumulated in the various records andbooks which have been kept. It is thought that a brief review of theresults, and a summary of the records in tabular form, will be ofinterest to the members of the Society, and it is also hoped that thediscussion of this paper will bring out the comparative results ofoperation of other filter plants. As a matter of convenience, thefollowing general description of the plant is given.

Description of the Filtration Plant.—The Washington filtrationplant was completed and put in operation in October, 1905. It consistsof a pumping station for raising the water from the McMillan ParkReservoir to the filter beds; 29 filters of the slow sand type, havingan effective area of 1 acre each; the filtered-water reservoir, having acapacity of about 15,000,000 gal.; and the necessary piping and valvesfor carrying water, controlling rates of filtration, etc.

In the pumping station, there are three centrifugal pumps, which aredirectly connected to tandem compound engines; two sand‑washerpumps; three small electric generating sets for furnishing electriclight; and four 200‑h.p., water-tube boilers.

Each of the centrifugal pumps has a nominal capacity of 40,000,000 gal.per day when pumping against a head of 21 ft., and eachsand‑washer pump has a capacity of 2,500,000 gal. when pumpingagainst a head of 250 ft. The electric light engines and generatorssupply the current for lighting the pumping station, the office andlaboratory and other buildings, and also the courts and interior of thefilter beds, and for operating a machine‑shop.

The filters and filtered‑water reservoir are built entirely ofconcrete masonry. The floors are of inverted groined arches on whichrest the piers for supporting the groined arch vaulting. All thisconcrete work is similar to that in the Albany, Philadelphia, andPittsburg filters.

The filters contain, on an average, 40 in. of filter sand and 12 in. offilter gravel. The gravel is graded from coarse to fine; the lower andcoarser part acts as part of the under‑drain system, a